Ukushiswa kukadoti Isithando somlilo sasesitofini

Ukusakaza okumelana nokushisa kuvamise ukwenziwa ngezinsimbi ezingenazinsimbi ezinezibalo eziphezulu zeChromium neNickel. Ukusakazwa okwenziwe ngama-alloys amelana nokushisa kuhle kakhulu kuzinto ezivezwe amagesi omile emazingeni okushisa aphezulu isikhathi eside. Izimboni ezizuza ekusakazweni okungahambisani nokushisa kufaka phakathi Amandla, Izinjini, Izithando Zezimbiwa / Iziko, kanye nePetrochemical.

Ukufakwa kwensimbi okumelana nokushisa kubizwa nangokuthi ukusakazwa kwensimbi okungamelana namachibi, ukusakazwa kwensimbi okukhanyelayo, ukusakazwa kwensimbi engagqwali okushisa.

Insimbi engamelana nokushisa uhlobo lwensimbi ye-alloy enamandla amakhulu emishini nokuqina okungcono kwamakhemikhali emazingeni okushisa aphezulu.

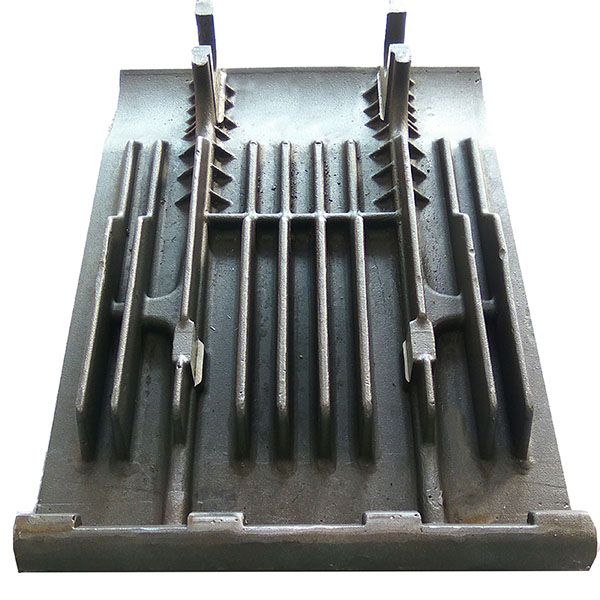

Ukufakwa kwensimbi okumelana nokushisa kusetshenziselwe ukwenza izingxenye ezingamelana nokushisa esithandweni sezimboni, isishintshisi sokushisa, isithando sokwelashwa esishisayo, i-grate epholile nezinye izinto zokusebenza ezingamelana nokushisa.

I-ASTM A297 ejwayelekile ihlanganisa ukukhishwa kwe-iron-chromium ne-iron-chromium-nickel alloy yensizakalo emelana nokushisa, amamaki ambozwe yi-ASTM A297 angama-alloys enhloso ejwayelekile futhi akukho mzamo owenziwe ukufaka ama-alloys amelana nokushisa asetshenziselwa uhlelo lokukhiqiza olukhethekile.

XTJ ngokuziqhenya ukunikela ukushisa ukumelana steel castings ukuthi ngokugcwele ukuhlangabezana ASTM A297 ejwayelekile, kufaka:

• I-ASTM A297 iBanga HF, Uhlobo 19Cr-9Ni

• I-ASTM A297 Ibanga HH, Uhlobo 25Cr-12Ni

• I-ASTM A297 Ibanga HI, Uhlobo 28Cr-15Ni

• I-ASTM A297 Ibanga HK, Uhlobo 25Cr-20Ni

• I-ASTM A297 iBanga HE, Uhlobo 29Cr-9Ni

• I-ASTM A297 iBanga HU, Uhlobo 19Cr-39Ni

• I-ASTM A297 Ibanga HW, Uhlobo 12Cr-60Ni

• I-ASTM A297 Ibanga HX, Uhlobo 17Cr-66Ni

• I-ASTM A297 Ibanga HC, Uhlobo 28Cr

• I-ASTM A297 Ibanga HD, Uhlobo 28Cr-5Ni

• I-ASTM A297 Ibanga HL, Uhlobo 29Cr-20Ni

• I-ASTM A297 Ibanga HN, Uhlobo 20Cr-25Ni

• I-ASTM A297 Ibanga le-HP, Uhlobo 26Cr-35Ni

Izindlela zokusakaza ezitholakalayo zokuphonsa insimbi engamelana nokushisa

1.Shell Isikhunta Precision thusi

2. Ukutshalwa kwezimali