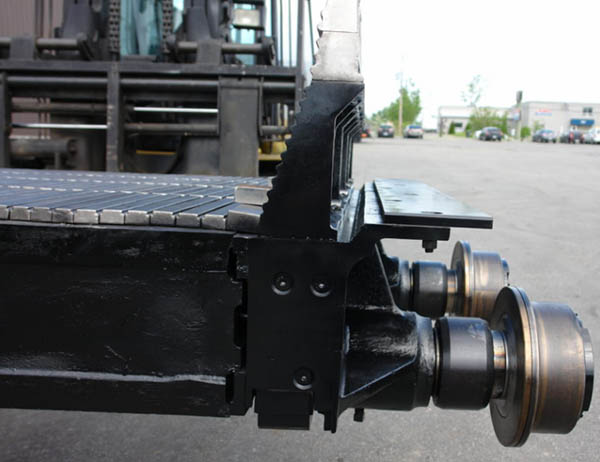

Ibha leGrate nodonga oluseceleni, Gqoka Izingxenye ezimotweni zepallet nezimoto ze-sinter / pellet

1. Inqubo yokulingisa: I-Shell isikhunta ngokunemba ekubunjweni

2. Ibanga lensimbi: 1.4777 1.4823 1.4837 1.4848

3.Ukubekezelela okukodwa kwe-cast: I-DIN EN ISO 8062-3 ibanga le-DCTG8

4.Ukubekezelelana kwe-Geometrical of cast: I-DIN EN ISO 8062 - ibanga le-GCTG 5

5. Isicelo: Gqoka Izingxenye ezimotweni ze-pallet nezimoto ze-sinter.

Singabahlinzeki abahola phambili ezimotweni ze-pallet nabakhiqizi bezimoto ze-sinter kanye nezigayo ezinkulu zensimbi. Ngolwazi lokulingisa olungaphezu kweminyaka eyi-10, lezi zingxenye ezingamelana nazo ezikhiqizwa yithi zihlala zinezinto ezinhle zomshini nendawo ebonakalayo yabalingisi. Ubuchwepheshe obuvuthiwe bulawula kahle izindleko zethu zokukhiqiza, ukuze ukwazi uku-oda imikhiqizo ebiza kancane kithi. Eminyakeni yamuva nje, ukwanda komthamo wokukhiqiza nakho kuqinisekisile usuku lwakho lokulethwa.

Insimbi yebanga esivame ukuyisebenzisa. Kungaba futhi njengezidingo zakho.

Ukwakhiwa kwamakhemikhali% wensimbi GX130CrSi29 (1.4777): EN 10295-2002

|

C |

Si |

Mnu |

Ni |

P |

S |

Cr |

Mo |

|

1.2 - 1.4 |

1 - 2.5 |

0.5 - 1 |

ubuningi 1 |

ubuningi be-0.035 |

ubuningi 0.03 |

27 - 30 |

ubuningi 0.5 |

Ukwakhiwa kwamakhemikhali% wensimbi GX40CrNiSi27-4 (1.4823): EN 10295-2002

|

C |

Si |

Mnu |

Ni |

P |

S |

Cr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

ubuningi 1.5 |

3 - 6 |

ubuningi be-0.04 |

ubuningi 0.03 |

25 - 28 |

ubuningi 0.5 |

Ukwakhiwa kwamakhemikhali% wensimbi GX40CrNiSi25-20 (1.4848): EN 10295-2002

|

C |

Si |

Mnu |

Ni |

P |

S |

Cr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

ubuningi 2 |

19 - 22 |

ubuningi be-0.04 |

ubuningi 0.03 |

24 - 27 |

ubuningi 0.5 |

Ukwakhiwa kwamakhemikhali% wensimbi GX40CrNiSi25-12 (1.4837): EN 10295-2002

|

C |

Si |

Mnu |

Ni |

P |

S |

Cr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

ubuningi 2 |

11 - 14 |

ubuningi be-0.04 |

ubuningi 0.03 |

24 - 27 |

ubuningi 0.5 |

| Izici zemishini (ASTM A297 Ibanga HH) 1.4837 | I-UTS: Min 75 Ksi / 515 Mpa |

| YS: Min 35 Ksi / 240 Mpa | |

| Ukunwebeka: ku-2 ku: Min 10% | |

| Ubulukhuni: Min 200 BHN (izindawo ezi-3 ngobuningi) " | |

| Microstructure / Metallography | Ngokuyinhloko isakhiwo sase-Austenitic esiqukethe ama-carbides ahlakazekile |

| I-SoundnessTest / i-X-ray noma i-UT | I-RT nge-ASTM E446 Level II ngayinye |

| UT nge-ASTM A609 Level II | |

| NDT / LPI noma i-MPI | MPI ngokwe-ASTM E709 / E125 LEVEL II |

| I-LPI ngokwe-ASTM E165 Level II " | |

| Ukuhlolwa Kokugcina Okubukwayo | I-ASTM A802 Izinga II |

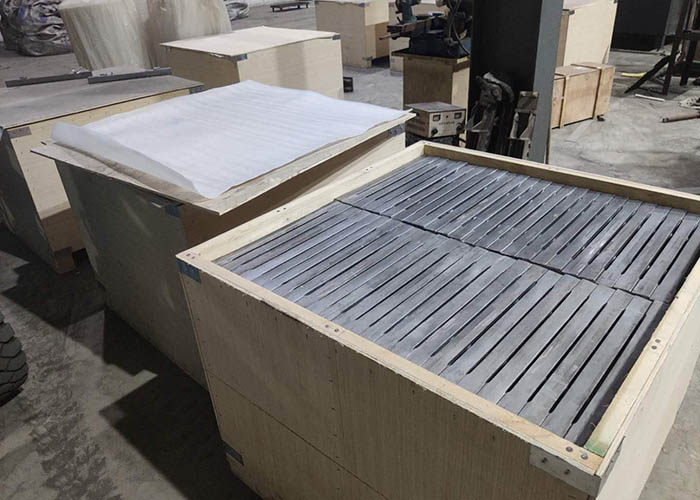

| Iphakheji | Icala le-Iron noma i-Wooden case. |

Emnothweni wamanje wokuncintisana, ukugcina ikhwalithi ngenkathi ukunciphisa izindleko kungaba yinselelo kuwo wonke amabhizinisi.

Kepha ukubambisana ne-xtj, awudingi ukucabanga ngakho. Singabantu ifektri professional, supply ngqo emva ukukhiqizwa. Futhi kunezisebenzi zobuchwepheshe eziqeqeshiwe kanye neqembu langemva kokuthengisa ukukunikeza ngezinsizakalo zobuchwepheshe. Ngale ndlela, ungathola insizakalo enhle kakhulu ngenkathi unciphisa izindleko.

Ngeminye imibuzo noma ngemibuzo yezobuchwepheshe, sicela uxhumane neThimba Lezinsizakalo le-XTJ. Sizokunikeza isisombululo esinengqondo kunazo zonke kanye nekhotheshini engcono kakhulu ngokusho komkhiqizo wakho.