Sakaza imigoqo yensimbi yensimbi, gqoka izingxenye zikadoti esithandweni samandla

1. Inqubo yokulingisa: I-Shell isikhunta ngokunemba ekubunjweni

2.Ibanga lensimbi: GX130CrSi29 (1.4777) (Futhi ingaba yimfuneko yakho)

3.Ukubekezelela okukodwa kwe-cast: I-DIN EN ISO 8062-3 ibanga le-DCTG8

4.Ukubekezelelana kwe-Geometrical of cast: I-DIN EN ISO 8062 - ibanga le-GCTG 5

5. Isicelo: Ukusingathwa kwezitshalo ezishisa amandla.

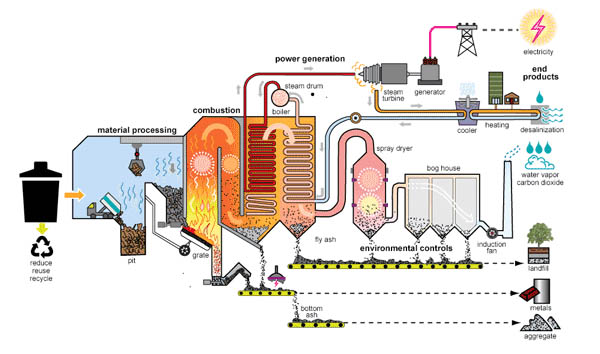

Ukulahlwa kukadoti manje sekuyinkinga enkulu kakhulu emhlabeni. Udoti wamandla yindlela yokwelashwa enengqondo njengamanje. Eminyakeni yamuva nje, amazwe amaningi anamandla aqinile kwezomnotho aseqalile ukunaka leli phuzu. Kutshalwe imali eningi ekwakhiweni kwezikhungo zamandla okushisa imfucuza. Lokhu akulethanga kuphela intuthuko enkulu emvelweni yethu. Ngasikhathi sinye, kusilethele izinzuzo ezinkulu kwezomnotho.

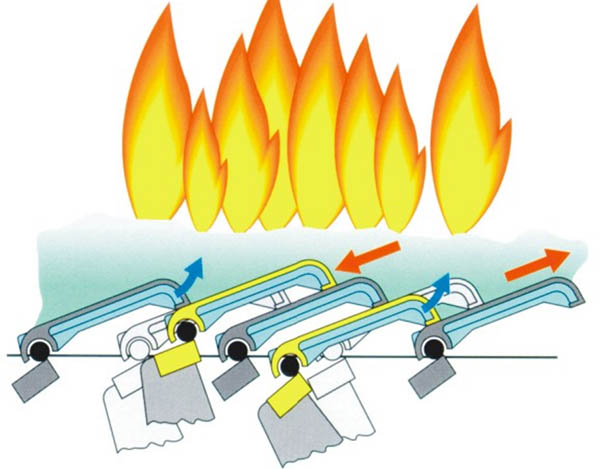

Njengoba kukhonjisiwe kulesi sibalo, imigoqo yama-grate idlala indima ebalulekile ekushisweni kwemfucuza. Ekushiseni okuphezulu nemvelo enokhahlo kakhulu, i-Low yekhwalithi ephansi izothinta kakhulu ukusebenza kahle kokushiswa kwemfucuza, futhi impilo yayo yesevisi ifushane kakhulu. Udinga ukuyibuyisela kaningi.

Kodwa-ke, njengoba uneminyaka engaphezu kwengu-10 usakaza isipiliyoni, singakuxazululela izinkinga zakho.

Insimbi yebanga esivame ukuyisebenzisa. (Kungaba futhi njengezidingo zakho.)

Ukwakhiwa kwamakhemikhali% wensimbi GX130CrSi29 (1.4777): EN 10295-2002

|

C |

Si |

Mnu |

Ni |

P |

S |

Cr |

Mo |

|

1.2 - 1.4 |

1 - 2.5 |

0.5 - 1 |

ubuningi 1 |

ubuningi be-0.035 |

ubuningi 0.03 |

27 - 30 |

ubuningi 0.5 |

Ukwakhiwa kwamakhemikhali% wensimbi GX40CrNiSi27-4 (1.4823): EN 10295-2002

|

C |

Si |

Mnu |

Ni |

P |

S |

Cr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

ubuningi 1.5 |

3 - 6 |

ubuningi be-0.04 |

ubuningi 0.03 |

25 - 28 |

ubuningi 0.5 |

Ukwakhiwa kwamakhemikhali% wensimbi GX40CrNiSi25-20 (1.4848): EN 10295-2002

|

C |

Si |

Mnu |

Ni |

P |

S |

Cr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

ubuningi 2 |

19 - 22 |

ubuningi be-0.04 |

ubuningi 0.03 |

24 - 27 |

ubuningi 0.5 |

Ukwakhiwa kwamakhemikhali% wensimbi GX40CrNiSi25-12 (1.4837): EN 10295-2002

|

C |

Si |

Mnu |

Ni |

P |

S |

Cr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

ubuningi 2 |

11 - 14 |

ubuningi be-0.04 |

ubuningi 0.03 |

24 - 27 |

ubuningi 0.5 |

| Izici zemishini (ASTM A297 Ibanga HH) 1.4837 | I-UTS: Min 75 Ksi / 515 Mpa |

| YS: Min 35 Ksi / 240 Mpa | |

| Ukunwebeka: ku-2 ku: Min 10% | |

| Ubulukhuni: Min 200 BHN (izindawo ezi-3 ngobuningi) " | |

| Microstructure / Metallography | Ngokuyinhloko isakhiwo sase-Austenitic esiqukethe ama-carbides ahlakazekile |

| I-SoundnessTest / i-X-ray noma i-UT | I-RT nge-ASTM E446 Level II ngayinye |

| UT nge-ASTM A609 Level II | |

| NDT / LPI noma i-MPI | MPI ngokwe-ASTM E709 / E125 LEVEL II |

| I-LPI ngokwe-ASTM E165 Level II " | |

| Ukuhlolwa Kokugcina Okubukwayo | I-ASTM A802 Izinga II |

| Iphakheji | Icala le-Iron noma i-Wooden case. |

Imakethe yethu eyinhloko

Izinkampani ze-OEM nezobunjiniyela

Imfucuza yezitshalo zamandla

Izinkampani ezisebenzayo

Amayunithi we-Biomass

Izitshalo zamandla ezisebenza ngamalahle

Izinkampani zensizakalo zemisebenzi yesondlo

Izinhlobo ezahlukene zemigoqo ye-OEM grate

Amabha we-grate aqediwe kahle

Inqubo Yokuvuthwa Nokulawulwa Kwekhwalithi Okuqinile Kungani uzokhetha thina

Ngeminye imibuzo noma ngemibuzo yezobuchwepheshe, sicela uxhumane neThimba Lezinsizakalo le-XTJ. Sizokunikeza isisombululo esinengqondo kunazo zonke kanye nekhotheshini engcono kakhulu ngokusho komkhiqizo wakho.